RS TMT-500, 550D

श्री RAGHUVIR STEEL PVT LTD(RSPL) an emerging organization incorporated by Young & Enthusiastic entrepreneurs with an experience of almost 2 decades in steel industries. Now RSPL has set up most advanced SMS and Hot-Rolling Mill projects in the heart of Saurashtra - Rajkot.

The introduction of RS TMT-500D Rebar has important implications for everyone involved in reinforced concrete design and construction.

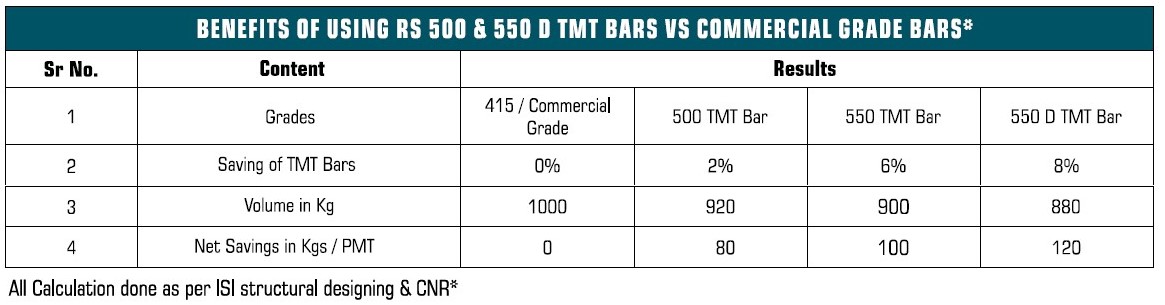

With an increase in minimum yield strength 500 MPa, & 550 MPa has become more efficient and cost-effective. There is a direct material cost savings of around 10% to 12% obtainable on most projects. Builders will also benefit from simplified reinforcement detailing.

New Measures for Ductility

Key Changes to IS 13920 : 1993 include the introduction of new measures of ductility, with steel types classified based on mechanical properties which has been termed as 500D & 550D. In addition Bureau of Indian Standards has combined all reinforcing steel types into the one Standard, IS 1786-2008, replacing IS 1786 - 1984.

Requirements in the revision of IS 13920:1993 and the new reinforcing steel materials Standard Fe 500D & Fe 550D (IS 1786 – 2008).

-

RS TMT

500 -

RS TMT

550D

BAR TYPES

The majority of RS TMT -500D & 550 D Rebar is made by the

THERMEX process, which results in a reinforcing steel with a carbon equivalent (CE) limit of 0.39 max.

RS TMT-500D & 550D Rebar is suitable for use with all types of mechanical splicing systems for joining steel reinforcement like welding of different types for various designs.

In addition, (RS TMT CRS – 500D & 550D) has more corrosion resistance because of the unique treatment & microstructure (BONDING characteristics) formed in the process.

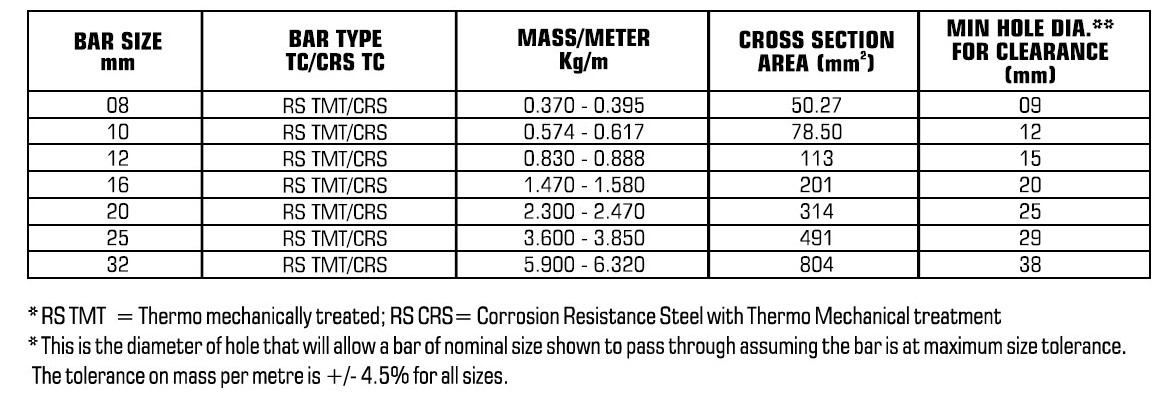

DIMENSIONS & MASS

STRENGTH AND DUCTILITY PROPERTIES

Carrying on the Thermo Mechanical Treatment Tradition (THERMEX TECHNOLOGY)

Thermex Technology is one of the processes in manufacturing TMT bars. This technology is from Germany. This technology will give 2 layers in the core of the TMT bars. Outer layer is Martensite and the inner core is Pearlite. This unique formation will give good mechanical properties which can withstand the seismic zone.

RS TMT 500D & 550D Rebar produced by Shri Raghuvir Steel Pvt Ltd has high strength because of unique, patented, mill heat treatment process. The tough outer skin and ductile core of RSTMT 500 D & 550 D results in a reinforcing bar with exceptional toughness, ductility and bendability.

The supply of RS TMT 500 D & 550 D rebar is on the basis of conformance to batch test results as defined in the proposed new Standard. This will include at least three tests per batch, with the following property requirements:

- Average of batch results to exceed 530 MPa, with no individual result below 525 MP ( RS 500D)

- Average of batch results to exceed 570 MPa, with no individual result below 560 MP ( RS 550D)

Average of batch test results will be not less than the characteristics values. Sufficient production has been completed; statistical data for assessment of conformance to the long term quality levels for determination of characteristic values are also available.

DIMENSIONS & MASS

Average of batch test results will be not less than the characteristics values. Sufficient production has been completed; statistical data for assessment of conformance to the long term quality levels for determination of characteristic values are also available.

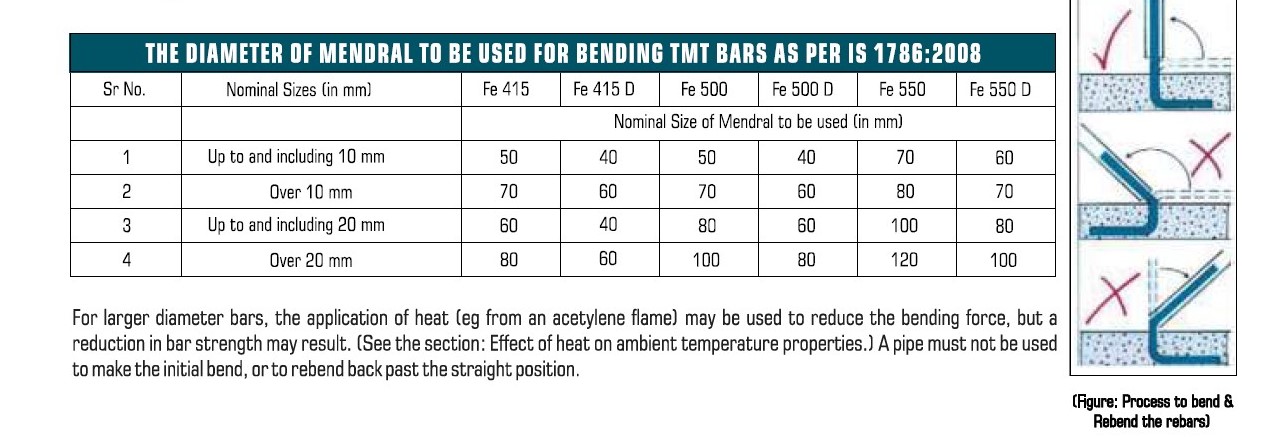

A number of situations many arise where bars must be bent or rebent on site, or where Pre-bent bars must be straightened. For smaller diameter bars (eg., 08, 10, 12 and 16mm), this is preferably performed at ambient temperatures, as this has the least effect on steel properties. The following guidelines should be observed.

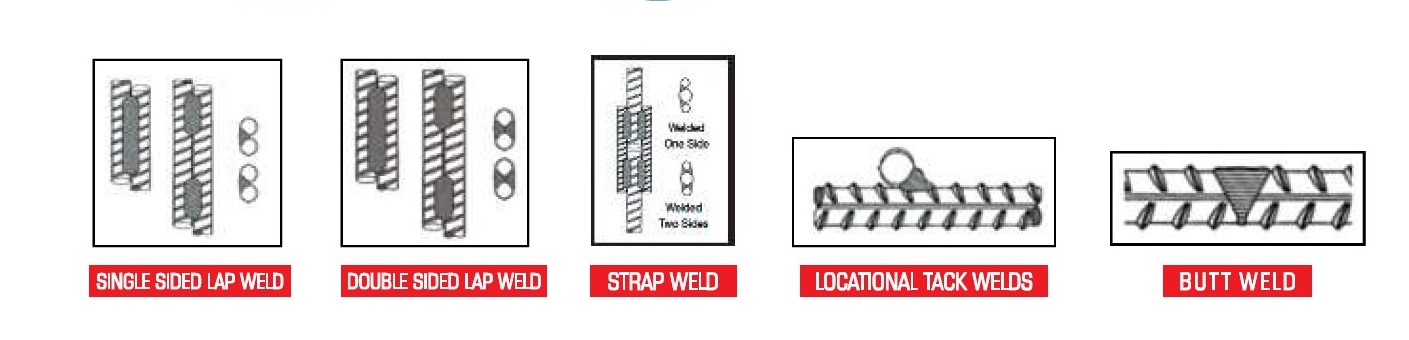

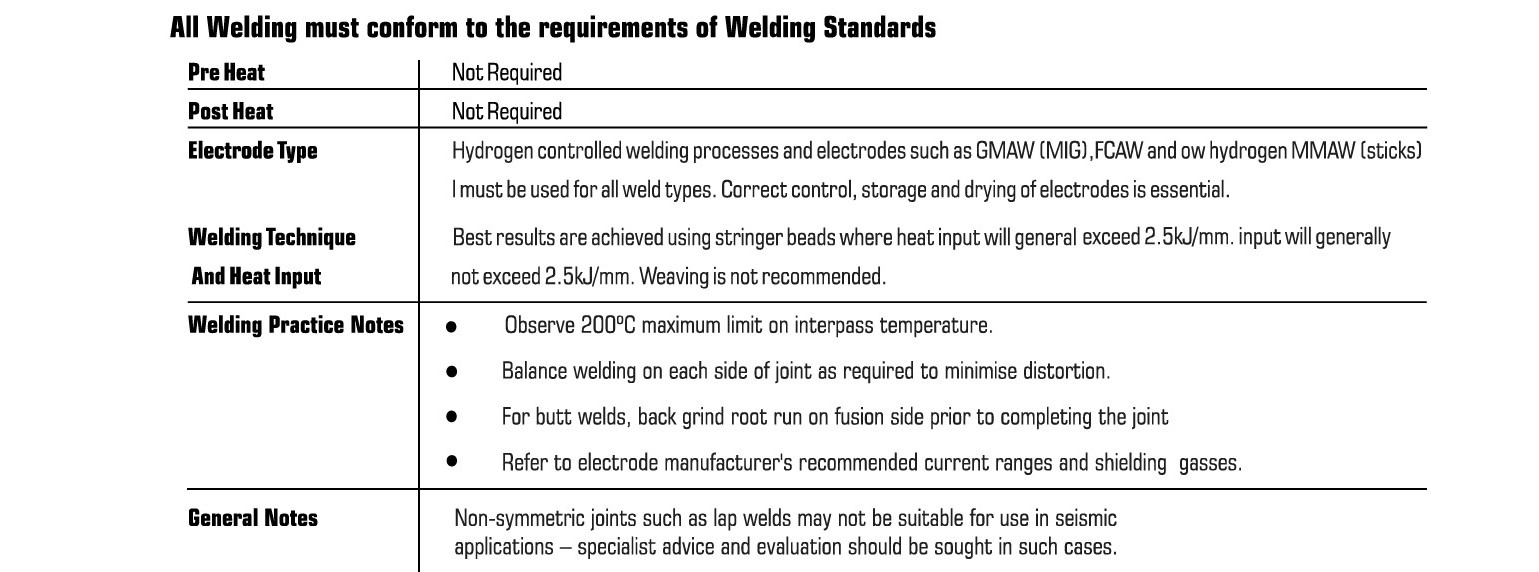

WELDING RS TMT -500D & 550D REBAR

RS TMT-500D & 550D Rebar produced has a carbon equivalent (CE) limit of 0.39 max and, as such, requires no pre-heating prior to welding.

RS TMT CRS – 500D& 550D rebar has a carbon equivalent limit of 0.44 max, however, will still not require pre-heating when welded in accordance with the revised Welding Standards.

Other manufacturers’ 500 MPa reinforcing steel may be made to higher CE limits and pre-heating may then be required in certain circumstances e.g. for tack & lap welding of larger bars.