RS TMT : Quality Process

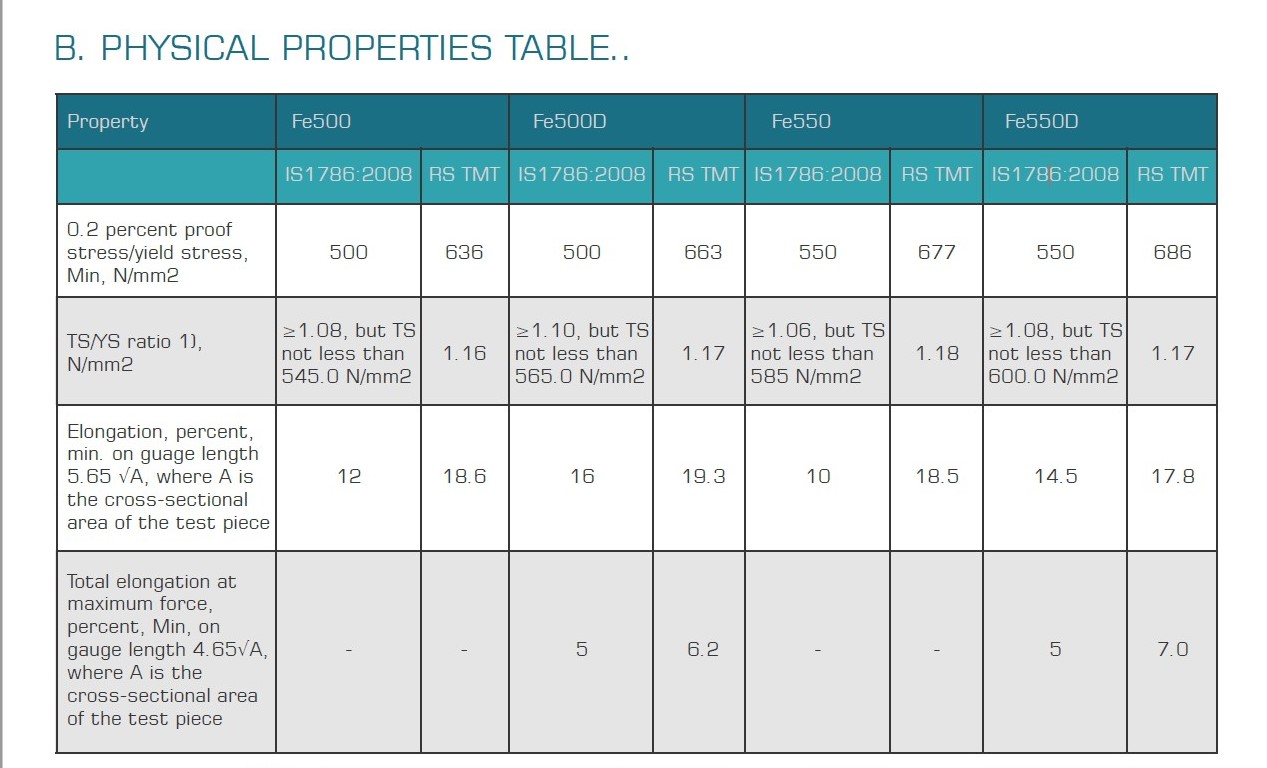

The quality is at par with any brands in the state. We assure that the physical properties like Yield & Tensile strengths, minimum 15% elongation is within the range specified by BIS. The most important quality issue in TMT bars is widely known as the CV (Characteristic value) of bars. This particular test will prove the quality of the bar. RS TMT is one such premium quality bar to maintain CV as designated by BIS.

RS TMT- 500D & 550D is rolled with an advanced technique to attain the tight dimensional values as per the BIS standards 1786-2008 and passed through the quenching system by GERMAN THERMEX TECHNOLOGY and self-tempered on the automatic cooling bed.

-SHRI RAGHUVIR STEEL PVT LTD(RSPL)

WHY RS TMT 500 D REBARS ?

It is the most important factor that determines the quality of a TMT bar. Thermo-mechanical Treatment, better known as the TMT route is considered as the most advanced manufacturing process. This PLC controlled online process is executed in three consequent stages namely Quenching, Self-tempering and Atmospheric cooling. It ensures a unique combination of strength and ductility in the steel TMT bars.

Due to Thermex Technology, ductile strength of a TMT bar ensures superior structure. The strength and ductility measure is specified in IS:1786 standard. Well surpassed limitation of the specified standard represents better quality of the TMT bar.

Performance of a concrete structure is relatively dependent on the rib style of the TMT bars and the steel-concrete bond for that particular structure. Two or more angular ribs, equally spread around the surface, are necessary to uphold the concrete bond and the tensile load of the structure at large.

Low carbon content in TMT bars makes it easy for welding works. Excellent weldability in steel rebar requires no pre or post welding treatment and makes it easier for the construction workers.

Advanced quenching process toughens the surface layer yet the core remains soft, this in turn makes the TMT bar easily bendable. The cutting and bending strength can be determined as per the Bar Bending Schedule (BBS) certification.

Nominal values specified in BIS code determine the grades of dimension tolerance. Closer values of sectional weight ensure higher meterage per unit weight in good quality TMT bars, compared to ordinary rebar.

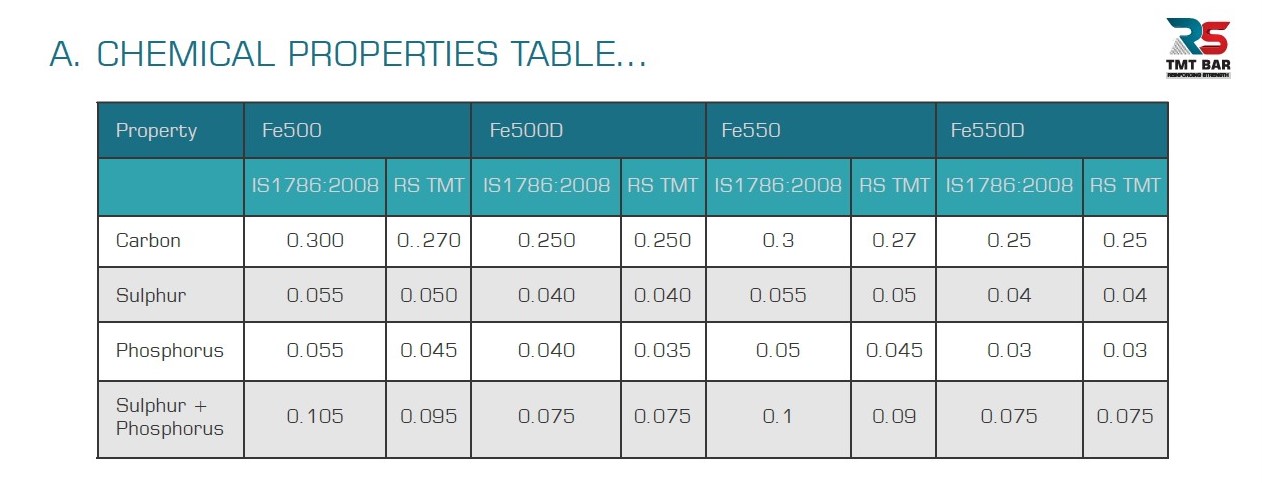

Certified composition of sulphur, carbon and phosphorus and exclusion of unwanted materials such as cast iron, non-metallic and non-ferrous etc. are the determinants of a good quality TMT bar.

Seismic resistant structure is dependent on its reinforcement strength. Buildings that are compliant to the recent seismic building code and standards are obviously more capable of withstanding the earthquake damages. TMT bars along with a good concrete bond, fortify the tensile strength of a structure. However grades of TMT bar differ at different seismic zones.

Higher UTS/YS ratio and percentage determines the seismic property of a TMT bar. Uniform energy dissipation in every cycle is significant because of the higher ductile strength & superior eismic resistance in a good quality TMT Bar, which is crucial to reduce structural damage and human casualties.

Good quality TMT bars have higher thermal stability and retain more than 80% of their ambient temperature yield strength at 300° Thus makes the concrete structure safer in fire hazards.

-Fire Resistance

Batch to batch consistency and uniform sectional weight per unit minimizes steel wastage and makes it beneficial for the customers to buy TMT bars in small quantities as well.

-Cost Effectiveness