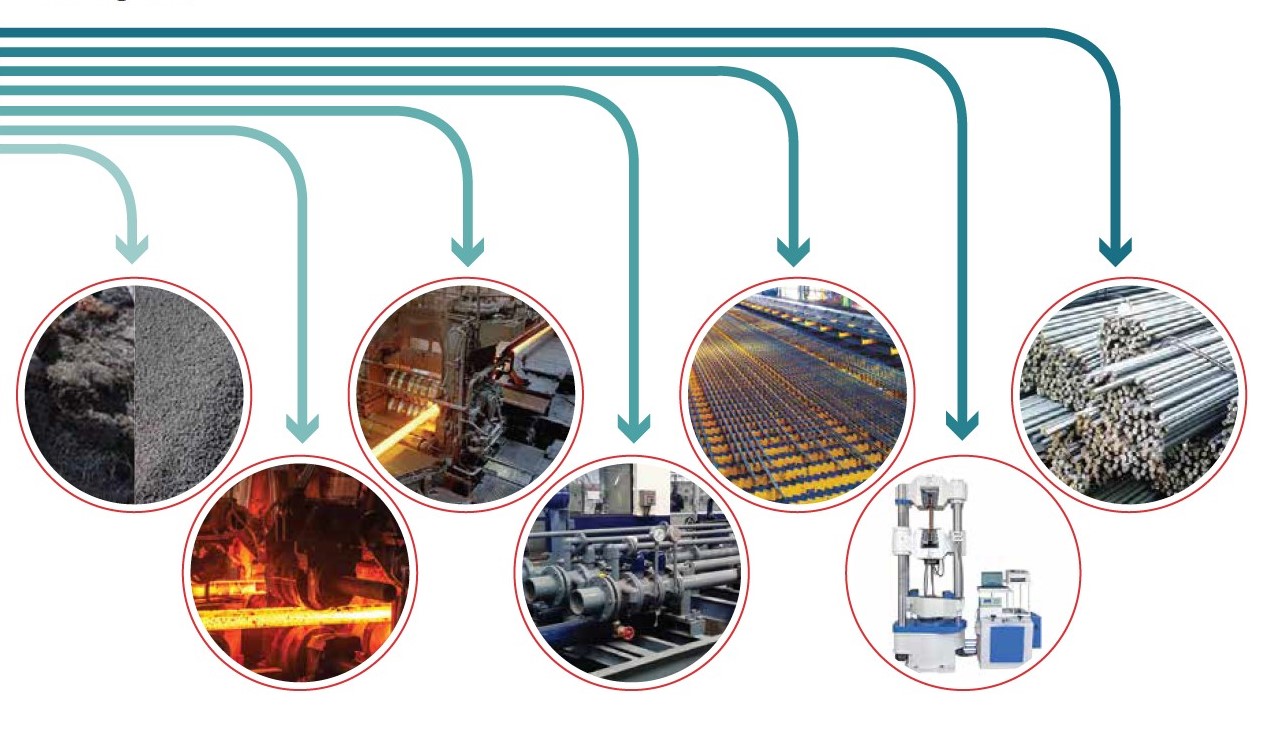

MANUFACTURING PROCESS OF RS TMT 500D & 550D REBARS

The quality of RS TMT differs from other similar products the way it is

manufactured. The different stages involved in the making of Steel and converted

into real quality and real strength TMT bars are being adopted in the RSPL

rolling mill.

Stag 1 :

Raw material

Making

Superior Quality, Tested & Segregated Raw material is melted in Electric furnace followed by addition of alloys as required to attain the desired Quality steel.

Stag 2 :

Billet making

Superior Quality, Tested & Segregated Raw material is melted in Electric furnace followed by addition of alloys as required to attain the desired Quality steel.

Stag 3 :

Rolling

The Hot Billet is conveyed to rolling mill stands, to pass through minimum 18 passes. To form their desired size & strength, this process is called “HOT CHARGING”. Hot charging is green manufacturing process as we omit coal consumption and develop environment friendly steel..

Stag 4 :

Quenching

The Hot TMT is here quenched & self tempered in German Technology based Thermex HEC. Equipment to attain the desire grades of TMT.

Stag 5 :

Self Tempering

Self Tempering on Automatic cooling Bed

The self tempered Bars are then transferred to 66 Mtr Automatic cooling Bed in order to cool naturally and retain the tempered strength in the TMT Bar..Stag 6 :

Quality Parameters

The Quality & Process are monitored on various stages and random samples of final product is taken from time to time to maintain the consistency of the premium quality “ RS TMT Bar”

Stag 7 :

Bundling & Packing

The TMT bars are then bundled marked with a unique tag for identity of RS TMT bars. This final product is delivered to all the clients through our strong distribution network.